EJ257 Engine Issues and the Type RA Solution

At Lakeview Automotive, we handle numerous Subaru EJ257 engine replacements every month. Alarmingly, a large number of Subaru vehicles equipped with EJ engines experience catastrophic failure with as little as 40,000 km on the odometer. The most common cause? Subaru’s fragile EJ pistons, which are prone to ringland failure, leading to severe engine damage. This widespread issue has been a hot topic in the Subaru community, and even spurred a class-action lawsuit against Subaru.

The Type RA Piston: A Solution to EJ257 Problems

Subaru finally took action in 2018 with the introduction of the Type RA Block. Nearly identical to the EJ257, the RA Block features upgraded "RA" pistons and became standard in all 2019+ Subaru STI models. These improvements have made RA engines significantly more reliable, capable of withstanding more power and stress. In fact, we haven’t replaced a single 2019+ Subaru STI engine due to piston failure, proving the effectiveness of this critical upgrade.

Understanding the Type RA Piston vs. the EJ257 Piston

To appreciate the improvements Subaru made, let's examine the key differences between the

Type RA piston and the

EJ257 piston, focusing on design and metallurgy.

Design Enhancements:

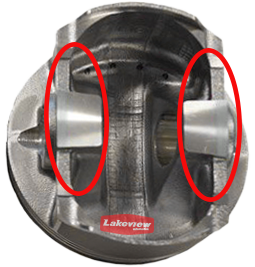

Subaru addressed the EJ257’s weaknesses by introducing the following vital upgrades in the RA pistons:.

Thicker Piston Crown: Increased by 2 mm to resist higher combustion pressures, and possibly heat from the combustion causing the rings to expand, thus reducing cracking.

Redesigned Piston Skirt: Reduces friction and piston slap while improving thermal efficiency.

Strengthened Pin Boss: Enhances durability at high RPMs.

These upgrades added just 10 grams to each piston—a negligible weight increase for a substantial improvement in durability. Combined, these changes make the Type RA pistons ideal for the rigorous demands of turbocharged engines.

Cast vs. Forged Pistons: What You Need to Know:

Despite the TYPE RA pistons remaining cast, the debate between cast and forged pistons often arises when discussing performance and reliability. Here’s how these two types compare, particularly in the context of Subaru EJ engines.

Cast Pistons: The Practical Choice

- Manufacturing Process: Made by pouring molten aluminum into molds.

- Advantages:

- Less expansion when heated, allowing tighter piston-to-wall clearances.

- Reduced piston slap, improving noise levels and minimizing wear.

- Enhanced engine efficiency and operational smoothness.

- Drawbacks:

- Less durable under extreme conditions compared to forged pistons.

Forged Pistons: Built for Performance

- Manufacturing Process: Created by compressing heated aluminum under intense pressure.

- Advantages:

- Exceptional strength under high heat and stress.

- Preferred for extreme Subaru performance builds exceeding 400 WHP.

- Drawbacks:

- Heavier, increasing rotating assembly weight.

- Greater thermal expansion, which increases piston slap and engine noise due to engine builders having to increase piston to wall clearance to accommodate.

Cast pistons are produced by pouring molten aluminum alloy into molds, where the metal solidifies into shape, resulting in a uniform but less dense grain structure. This structure provides adequate strength for standard applications but is less resistant to cracking or deformation under extreme stress or high temperatures. Thoughtful design improvements, such as reinforcing critical areas and enhancing heat dissipation, can significantly improve their durability and performance. Forged pistons, in contrast, are made by heating aluminum alloy and compressing it under high pressure, which aligns and compacts the grain structure. This process significantly enhances their strength, durability, and resistance to thermal and mechanical stresses, making them ideal for high-performance and heavy-duty applications.

The Verdict: RA Pistons Are a Balanced Solution

The cast RA pistons used in Subaru’s EJ257 Type RA engine deliver a balanced solution for most drivers. They offer excellent durability, thermal management, and reliability up to approximately 360 WHP. For those aiming for extreme power beyond 400 WHP, aftermarket forged pistons remain an option but come with trade-offs like increased noise and wear—making them less practical for daily drivers.

Contact us for Subaru Engine build options and pricing