Ford Mustang 7.3 Godzilla Engine Swap - Twin Turbo

Rob, a long-time client of ours contacted us in Late 2021 to start the dialogue on his 2012 Mustang Boss 302. Rob’s Boss 302 in a previous year had been in an accident and its factory “Road Runner” engine sold off. He got the car repaired at a body shop and sent it down to us to fill that empty void in the engine bay.

To put the rest of the story into perspective, Rob already has another Roush Charged Boss 302 at home.

As we pondered what to put into the engine bay we considered installing another Road Runner 302, however, the price on one of those units made it seem silly compared to a fully built Coyote with boost. But, Rob already has one of those at home... well kind of, minus the built part. He at the time had another Roush charged Red Boss 302 that we tuned up to 650 WHP.

AHA! What about one of those new “Godzilla” 7.3L pushrod Ford engines that are coming out in the new Superduty pickups? And of course, Sam, our man on the job insisted it would be twin turbo charged. So we presented it to Rob.

Rob is an avid drag racer, and when it comes to lining up to the tree there is no replacement for displacement, the Godzilla comes with acres of displacement compared to a Coyote based option. Moreover, Rob is an adventurous car guy, so with a vague quote, Rob Gave us the GO AHEAD! We called our parts supplier Western Motorsports and ordered lightly used takeoff 7.3 Godzilla. The motor looked so new when it came in we reckoned it was a “damaged in shipping to dealer” type take off.

Being so soon after the Godzilla 7.3 coming out, there was not much in terms of aftermarket support. There wasn’t even a forged rotating assembly option, or head studs. We knew this was going to be a matter of what can we get out of a fairly stock Godzilla plus boost. However, luckily we were able to secure a Callies Camshaft 220/226 – .630/.621. A mild cam good for boost.

First thing Sam did after getting his hands on the engine was to tear apart and file the rings down for boost.

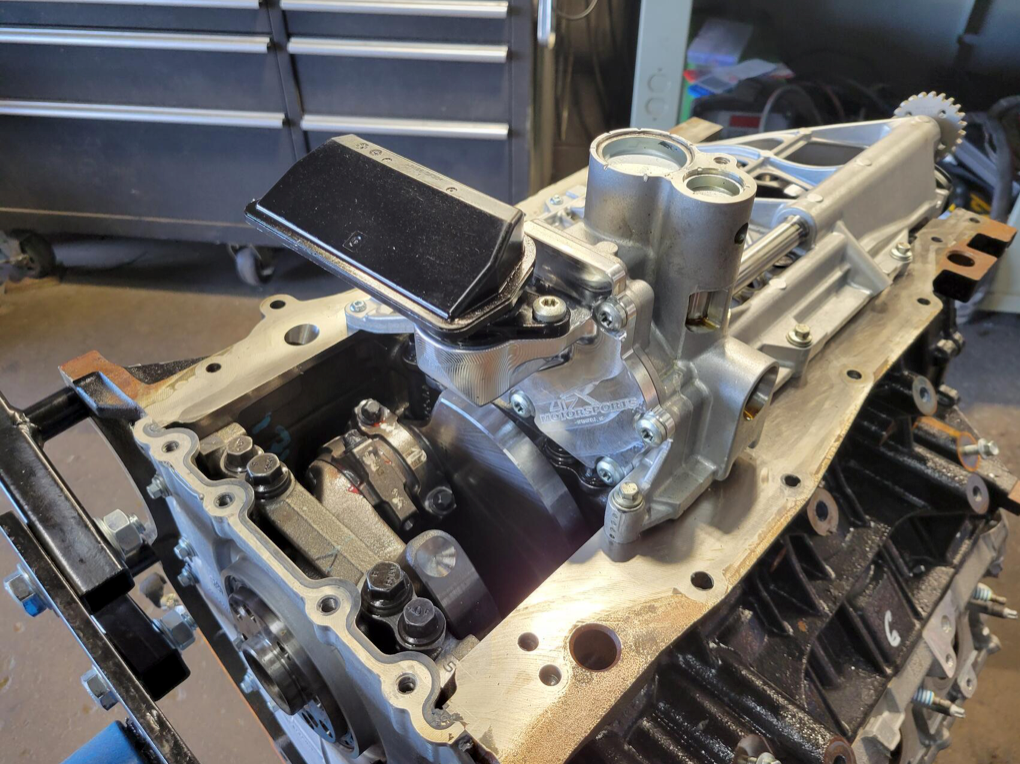

The 7.3 Godzilla while narrower than the Coyote, is a tall engine. We knew off the get-go we would have a solution for a low-profile oil pan. Luckily 417 Motorsports made a low profile pan for the Godzilla. Credit to 417 Motorsports for coming up with a clever solution. They designed a CNC machined oil pickup mod that sits directly on the oil pump. The original pickup used to sit on the staked plug, this gained 3 inches of clearance.

This is the pan setup all finished with after Sam welded on two AN bungs for the turbo drain lines.

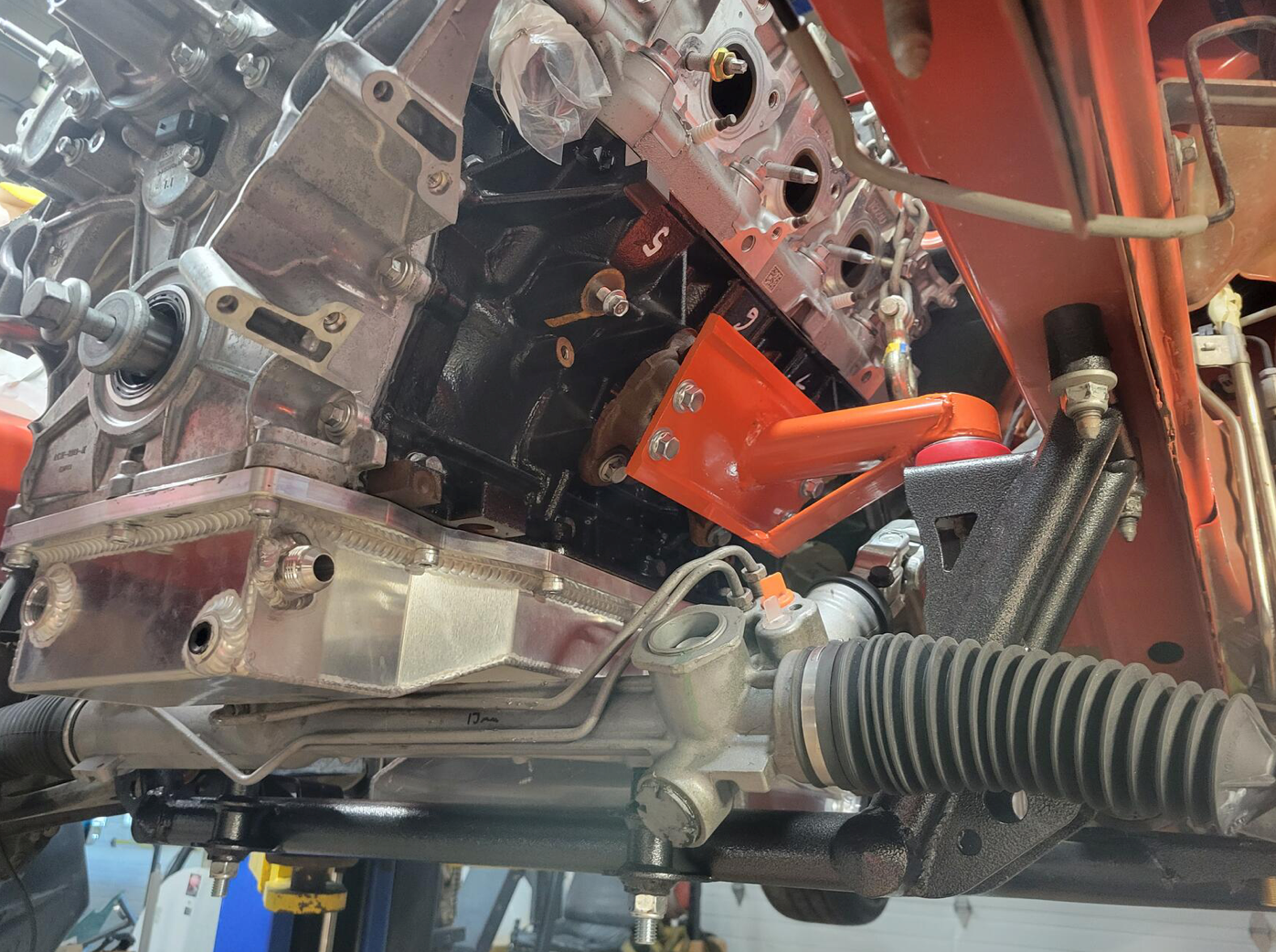

With the exhaust manifolds flipped around, time for the first test fit!

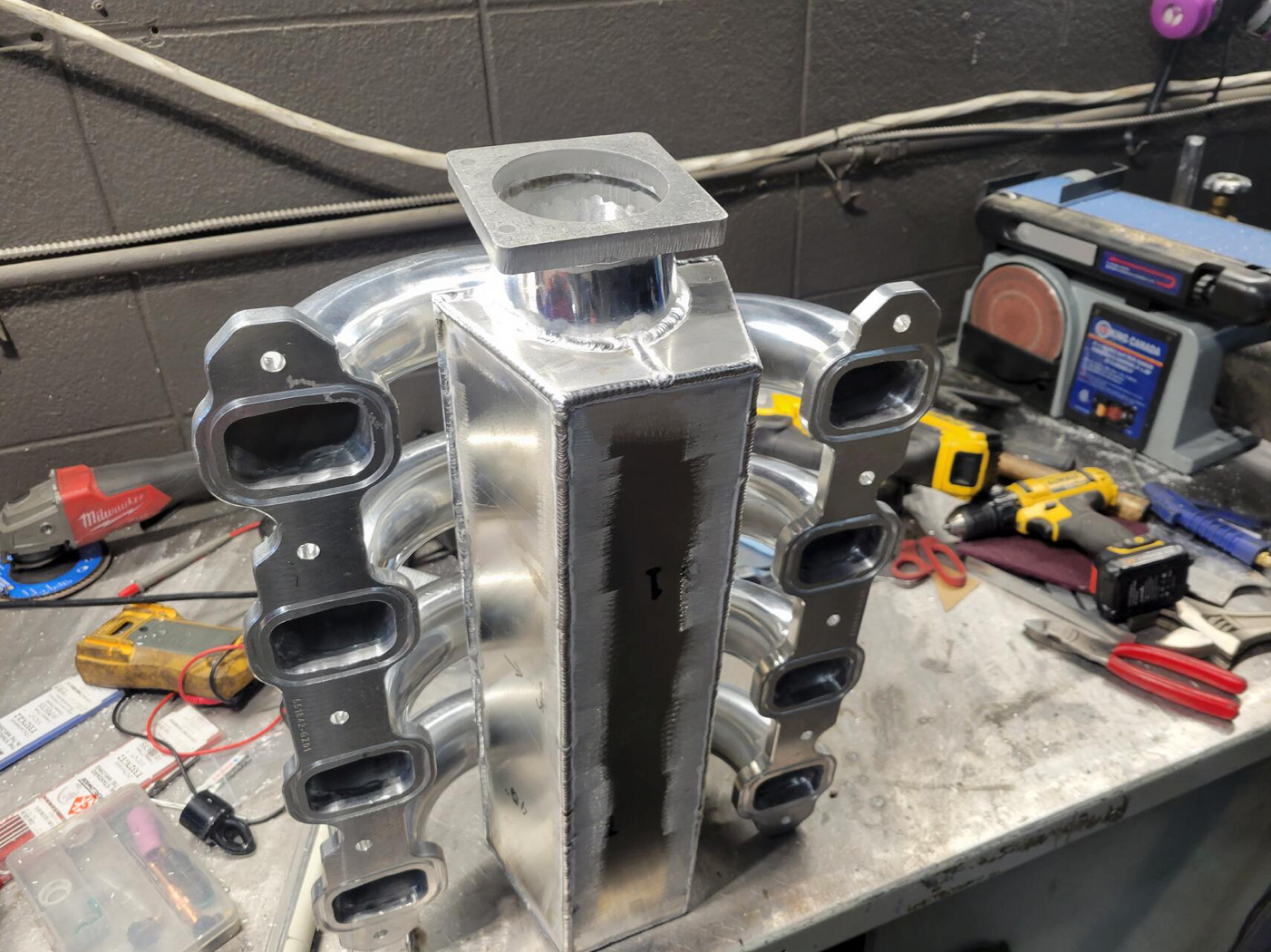

Yep… time to fabricate an intake manifold. No one at the time made one. Plus its pretty awesome to unleash your creative side and fabricate an intake manifold from scratch.

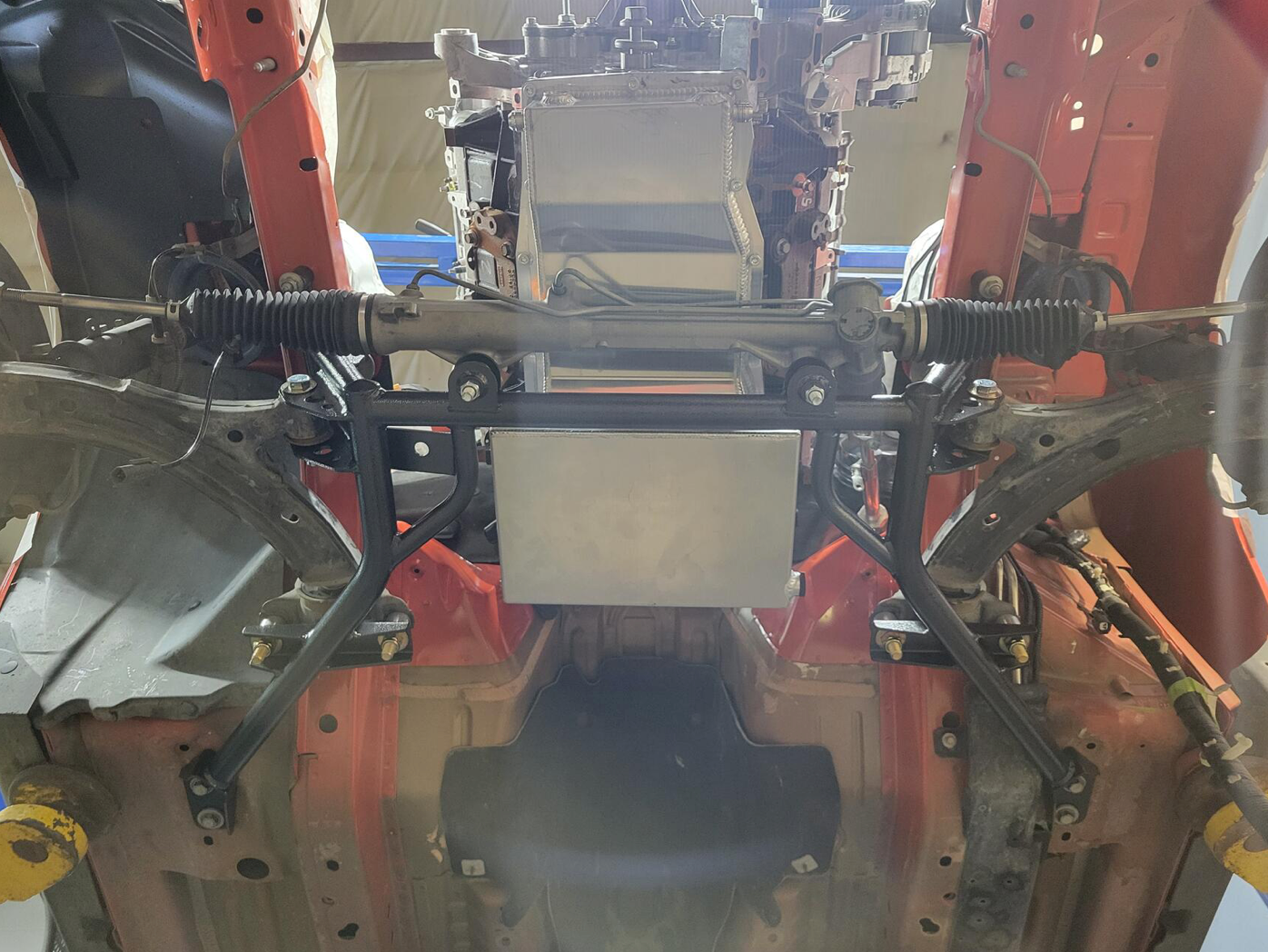

From the bottom we utilized a BMR tubular K member and a hydraulic power steering rack instead of the factory electric one. Too much space was being robbed by the factory setup.

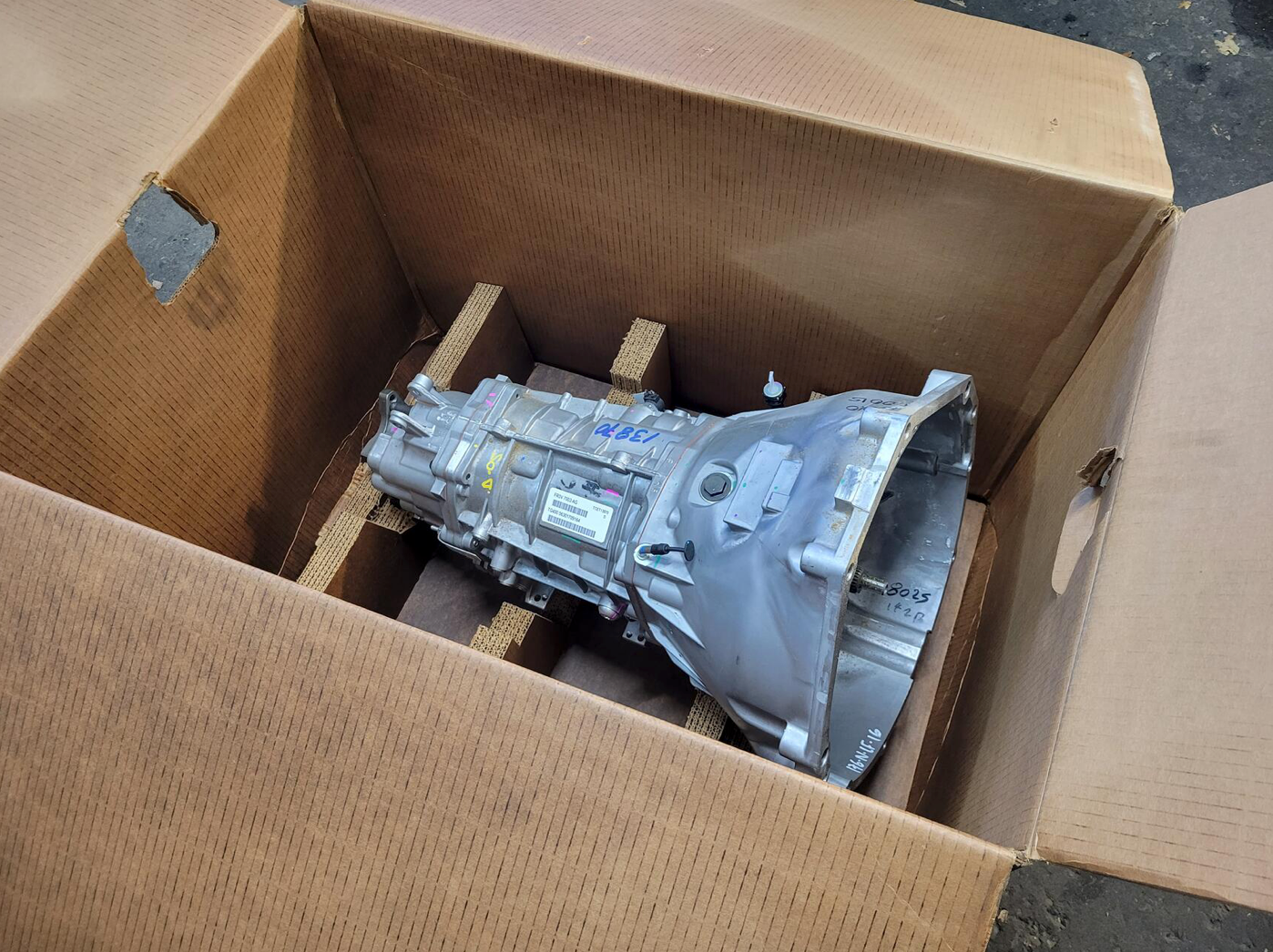

One of the smoothest shifting transmissions, the Tremec TR-3160 out of the Shelby gt350 was what we landed on for a trans for this build.

With everything mocked up and tranny bolted, Sam decided on a final location. Of course, as far back as we could take it.

Custom fabricated mounts seat the engine in place once and for all.

Engine mounts were fabricated from scratch by our man Sam. The amount of detail he put into building them shows his take on quality!

The original MT82 crossmember worked like a charm!

Fabrication on the intake manifold took a bit of time, however, it’s the first thing you see in the engine bay, it had to look good. In no way could we have utilized the plastic Ford manifold, it was too tall and the throttle body pointed up.

Turbo Setup

We went with a set of mirrored VS Racing 67/62 turbos. Getting them hooked up to the engine was all custom fabrication.

Our man Sam knows a thing or two about fabricating custom Turbo set ups. The original exhaust manifolds were luckily stainless and Sam was able to incorporate them, saved a lot of time.

Built a cooler stack with a radiator, AC condenser, and intercooler. Modified the radiator crossmember to make room for the intercooler. Welded elbows directly to the intercooler outlet to sneak it around the radiator.

Cut and welded elbows onto the compressor housings and made hot side charge piping.

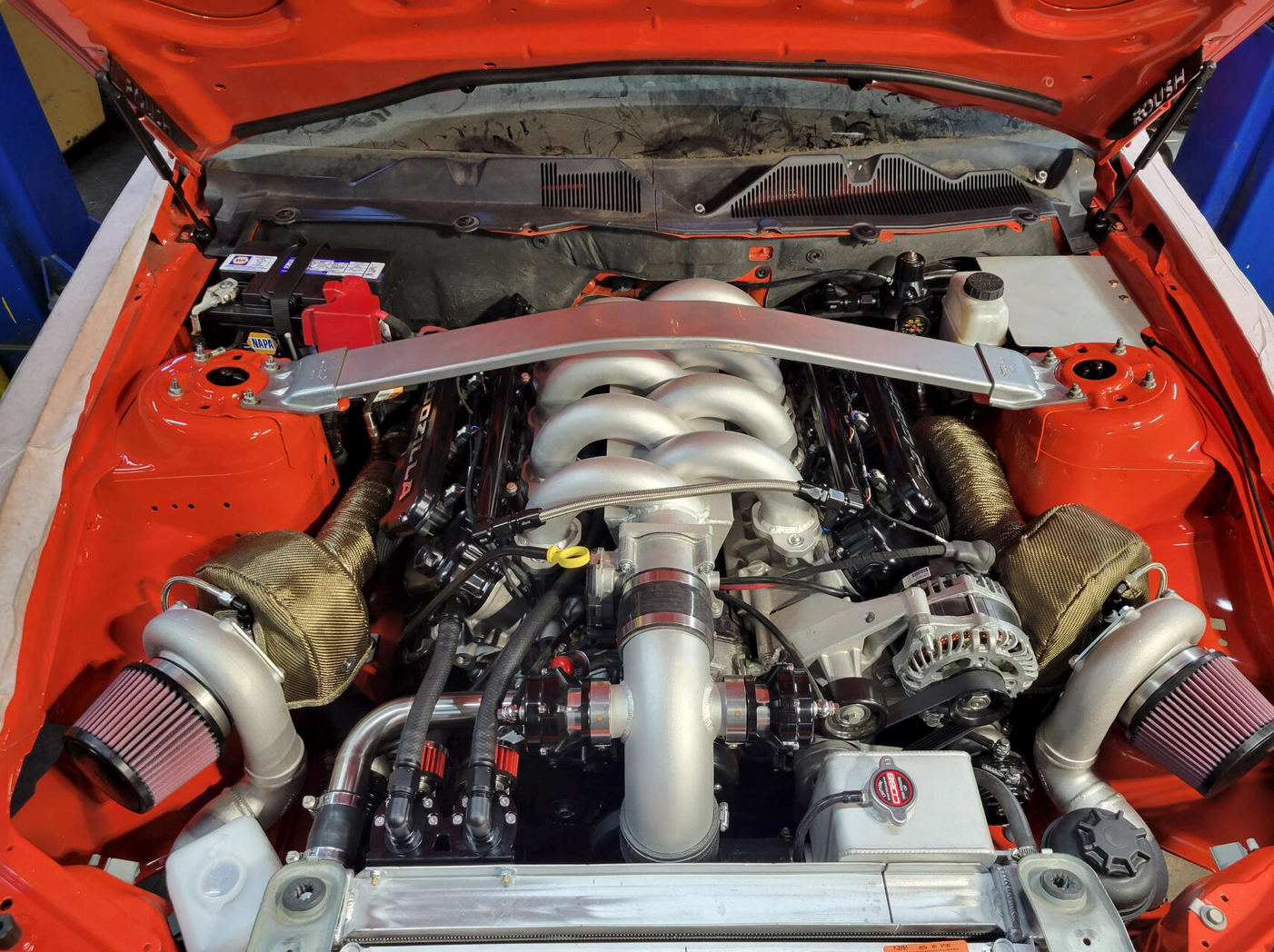

Turbo setup pretty much done. The engine is now also sporting some Holley fuel rails and Ford 80lb injectors.

Filling out the engine bay with hardware. PS reservoir, coolant tank, catch cans, washer tank.

Build wouldn’t be Complete without a custom tig exhaust with vacuum actuated dumps. The car is actually very quiet until we heard it all out on the dyno. Shook the whole shop!

For Gauges we went with the LCD Autometer dash.

Dyno Time!

It did exactly what we expected.

Tune 1 – 700 whp 775ftlbs on 10psi on pump gas

Tune 2 – 820 whp 901ftlbs on 14psi on pump gas

Those are big numbers on our Dyno, especially torque (Mustang Dynamometer). The key here is its essentially a stock engine with a cam, boost and on pump gas. For perspective, below is a comparison dyno graph between Boss-Zilla and a 3rd gen direct injected Roush Charged 13psi boost Coyote. Yes the Coyote heads will flow better with their 4 valves and yes the Coyote will rev higher out of the box, but in the end when big reliable power is what you’re after, there is no replacement for displacement.

For Rob this is an evolving build, he will race it for the time being and when he yearns for more power we will update it with all the new parts the industry has been brewing for these God-Zillas. We were very excited to be this early on the 7.3 scene!

The following is the basic build list.

- 2021 Ford 7.3 GODZILLA Super Duty take out engine

- Mcloed RTX Dual Disk Clutch

- BMR tubular K member

- Shelby GT350 Tremec TR-3160

- Five Bar Motorsports Controls Pac

- VSR Next Gen 67/62 Turbos

- Ford Performance Head Gasket KIT

- CALLIES CAMSHAFT 220/226 – .630/.621 – For Turbo APPLICATION

- 417 MOTORSPORTS GODZILLA SWAP LOW PROFILE OIL PAN

- FORE L2 FUEL SYSTEM – DUAL 430LPH PUMP

- FP 80LB Injectors

All prices on the site are subject to change, please request a quote for more accurate pricing.